Envia Systems announces breakthrough lithium-ion EV battery

Envia Systems announces breakthrough lithium-ion EV battery

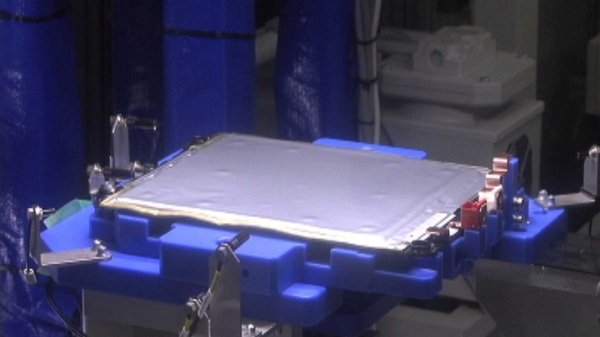

Today Newark, California based Envia Systems announced the development of a 400 watt-hour/kilogram rechargaeable lithium-ion battery. Of course, it’s just a prototype at this point, but with funding from the Advanced Research Projects Agency (ARPA). Just in case you didn’t know, ARPA, an agency of the U.S. Department of Defense, brought you the internet (originally known as the Arpanet). This new battery technology shows promise.

Envia expects this battery technology to provide the first realistically priced 300 mile range electric car. Using a Panasonic battery as a benchmark for power, Envia claims a 160% increase in energy density. While testing appears to back up these claims, one rather large red flag remains.

“Similar cells have been cycling in Envia’s test labs for over 300 cycles.”

Assuming the use of 50% of the capacity daily, this would provide less than two years of battery life. While low cost, high energy batteries are the holy grail of the electric vehicle (EV) manufacturers globally, the batteries must also accomplish other goals concurrently – long life among them. We need to see that cycle claim number get to well over 1,000 cycles for this to be a reasonable alternative. One other goal is high power density. Let us illustrate the point.

Let’s say that this battery offers a 160% increase in energy density. So a LEAF that can travel 73 miles according to the EPA can actually travel 117 miles with the same kilowatt hour sized battery. This is a significant improvement. But since these batteries are smaller and lighter, more modules can be stuffed under the car to provide our hoped for 200-300 mile range. But, if the energy density comes at the excessive loss of power, this would not be a good thing. Loss of power, in this instance, would equate to excessively long acceleration times – not due to a lack of power of the electric motor, simply that the battery can only provide so much power at a time.

Picture a large coffee urn with a variable flow spigot. A low power battery is the equivalent of being able to let the coffee flow into your cup painfully slow. There might be a gallon of coffee in the pot, but if the spigot won’t let it flow, you might be standing there awhile. But, there would still be a lot of coffee in the pot. So you can see that maximizing range while sacrificing power is not an acceptable solution. The question is – what is the power density of these batteries alongside the energy density.

Nissan has already produced high energy cells and high power cells. The high energy cell is optimized for full electric vehicles and the high power cell is optimized for hybrid electric vehicles. Nissan is likely using the high power cells in the Infiniti M Hybrid, and we will likely see these high power cells in future Nissan hybrid products.

Our point is that while the development of new technology should be encouraged, all aspects of vehicle (and battery) performance need to taken into consideration while developing and considering such technology.

Great talk here. As a bit of an aside, one of the benefits of getting packs big enough for 200 or 300 mile ranges in a vehicle have the added benefit of normally not getting deep discharge cycles (since few people will be driving 200 or 300 miles on a daily basis – if they can be coached to charge every night they’ll be getting shallow discharge cycles – this can positively affect capacity life and increase the lifetime of the packs.

Lots of cool stuff going on with batteries and expected to continue for the foreseeable future – I wish the cars would get a revision every 2 or 3 years as battery technology would be ready for a bump each time. Waiting 5 years till 2015 for Generation 2’s is a bit agonizing.

300 cycles doesn’t seem that bad to me. In a 300 miles pack, that represents 90,000 miles or about 6 years for the average driver (15,000 miles/year). They don’t seem to tell what the capacity loss is after those 300 cycles though.

What I found the most interesting is that they expect to have a selling price of 125 $/kWh (I presume that’s for the cells only).

Gwido – right… the $125 price point is only for the cell. That does not included packaging into modules which then get packaged into a battery pack. Still, it is moving in the right direction. We’re encouraged that so many organizations – for profit and academic – are looking into improving battery technology.